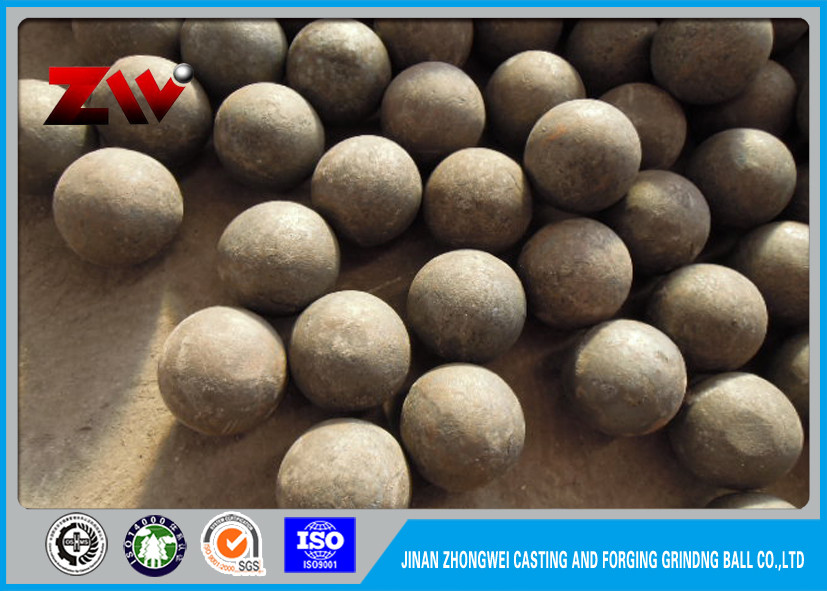

Forging Steel Balls 75Mr Grinding Media High Chrome Casting Ball

Products Name: Forged Grinding Ball, Forging Grinding Ball, Forged Ball, Forging Ball, Forged Steel Ball, Forged Grinding Steel Ball, Forged Steel Grinding Ball.

Process features of forged balls:

Forging forming---The raw material is forged to a certain deformation by air hammer,increase the compression ration,so that to dense the structure of wear-resistant ball and improve the toughness and hardness.

Forged steel ball:

The Forged ball is made by direct heating at high temperature and forging, and it do not need melting and casting. So this steel ball is called Forged steel ball.

1. Features of forging grinding media balls:

1). Even high hardness

2). Good wear-resistance

3). Unbreakable

4). High impact value

5). Production Capacity: 50,000mt per year

6). Low price

2. Applied fields of forged grinding balls: a) Mines; b) Cement plants; c) Power stations; d) Chemical industry

3. Raw Materials: B2; B3; B4; 60Mn;

4. Specifications of our products as follows:

Type and Chenical Composition of Forged Balls

|

Name

|

Material

|

Chemical Composition |

| C |

Si |

Mn |

S/P |

Cr |

HRC |

| Forged ball |

B2

|

0.72-0.85 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

0.4-0.6 |

58-6 |

|

Name

|

Material |

Impac test

(Ak.j/cm^2)

|

Endurance test

times

|

HRC |

Breakage |

|

Forged ball

|

B2 |

≥14 |

≥10000 |

58-64 |

<1% |

|

Nominal

diameter

|

Diametrical

Tolerance

|

Approx weigt

per ball

|

Average number

per MT

|

Microstructure |

| 25mm |

+1.5-0.5 |

0.064 |

15625 |

M+B+C |

| 30mm |

+1.5-0.5 |

0.11 |

9090 |

| 40mm |

+1.5-0.5 |

0.26 |

3846 |

| 50mm |

+1.5-0.5 |

0.51 |

1961 |

5.Package: Steel drums (850kg per drum) or Flexible Container Bags ( 1000kg per bag)

a.Dia .20mm-dia.150mm 1000kg per bags , 26bags max for the 20foot container

b.Dia.130mm-dia. 150mm 800kg per drum, 30drums max or the 20foot containe

Dia. 50mm-dia .127mm 850kg per drum , 28drums max for the 20footcontainer

Dia. 20mm-dia .40mm 900kg per drum , 26drums max for the 20foot container

Dimensions dia 55cm*88cm Volume 0.23cubic meter tare 15 kgs/teel drum

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!