low price forged steel grinding balls--ball mill grinding media

Products Name: Forged Grinding Ball, Forging Grinding Ball, Forged Ball, Forging Ball, Forged Steel Ball, Forged Grinding Steel Ball, Forged Steel Grinding Ball.

Process features of forged balls:

Forging forming---The raw material is forged to a certain deformation by air hammer,increase the compression ration,so that to dense the structure of wear-resistant ball and improve the toughness and hardness.

Forged steel ball:

The Forged ball is made by direct heating at high temperature and forging, and it do not need melting and casting. So this steel ball is called Forged steel ball.

Q:What can it do?

A:Our ball mill is used for wet grinding about fine and thick ore.

Q:Which industry can your ball mill use for?

A:Our ball mill is applied in mineral dressing, chemical industry and construction industry.

THE PROCESS LINE OF PRODUCTION:

1. Features of forging grinding media balls:

1). Even high hardness

2). Good wear-resistance

3). Unbreakable

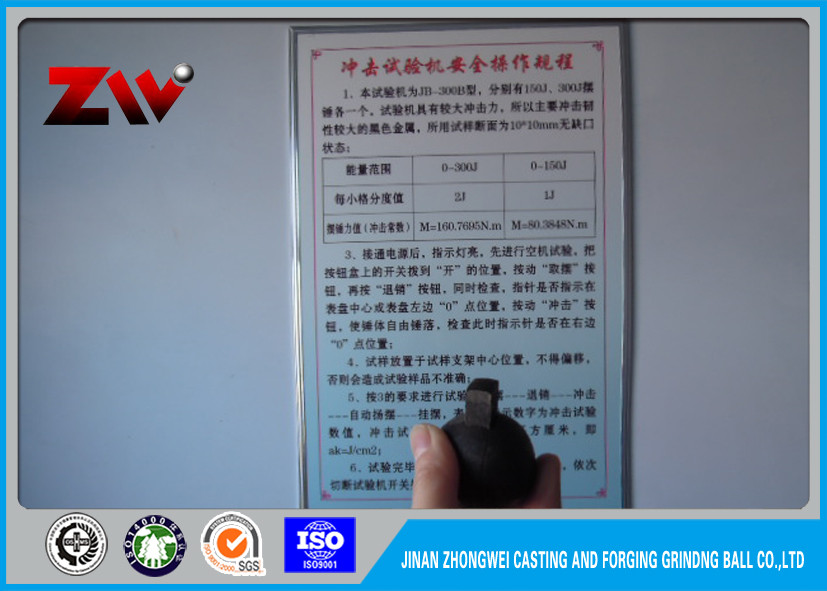

4). High impact value

5). Production Capacity: 50,000mt per year

6). Low price

2. Applied fields of forged grinding balls: a) Mines; b) Cement plants; c) Power stations; d) Chemical industry

3. Raw Materials: B2; B3; B4; 60Mn;

4. Specifications of our products as follows:

Type and Chenical Composition of Forged Balls

|

Name

|

Material

|

Chemical Composition |

| C |

Si |

Mn |

S/P |

Cr |

HRC |

| Forged ball |

B2

|

0.72-0.85 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

0.4-0.6 |

58-6 |

|

Name

|

Material |

Impac test

(Ak.j/cm^2)

|

Endurance test

times

|

HRC |

Breakage |

|

Forged ball

|

B2 |

≥14 |

≥10000 |

58-64 |

<1% |

|

Nominal

diameter

|

Diametrical

Tolerance

|

Approx weigt

per ball

|

Average number

per MT

|

Microstructure |

| 25mm |

+1.5-0.5 |

0.064 |

15625 |

M+B+C |

| 30mm |

+1.5-0.5 |

0.11 |

9090 |

| 40mm |

+1.5-0.5 |

0.26 |

3846 |

| 50mm |

+1.5-0.5 |

0.51 |

1961 |

5.Package: Steel drums (850kg per drum) or Flexible Container Bags ( 1000kg per bag)

a.Dia .20mm-dia.150mm 1000kg per bags , 26bags max for the 20foot container

b.Dia.130mm-dia. 150mm 800kg per drum, 30drums max or the 20foot containe

Dia. 50mm-dia .127mm 850kg per drum , 28drums max for the 20footcontainer

Dia. 20mm-dia .40mm 900kg per drum , 26drums max for the 20foot container

Dimensions dia 55cm*88cm Volume 0.23cubic meter tare 15 kgs/teel drum

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!