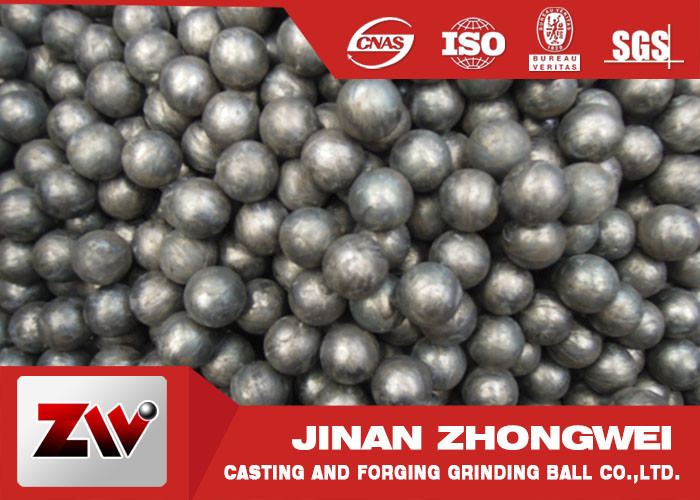

Good Wear Resistance Mining Special Use Forged And Casting Grinding Balls For Ball Mill

Jinan zhongwei casting and forging grinding ball Co.,ltd, as the powerful grinder of world’s mining,

specializes in the production of the forged steel ball, cast iron ball, cylpebs and grinding rods,

which

are widely used in the mining fields, chemical plant ,power station and building material industries .

We have exported to more than 20 countries such as South Africa, Australia, Chile, Kuwait, UAE,

Russia, Malaysia, Korea and Philippine etc.

Grinding Balls For Ball Mill Product performance

1. Even hardness

2. Unbreakable

3. Grinding resistant

4. High impact value

5. High combined efficiency of grinding mill

Grinding Balls For Ball Mill Application fields

1. Industries of cement building material

2. metallurgical selection in mine

3. grinding coal in power plant

4. chemical industry

5. machinery

Grinding Balls For Ball Mill Chemical Elements( Below is common used type all over the world,if you have any other different requirement, please let me know,we can order from steel mill)

Forged Steel Balls

| Material |

Chemical Elements |

| C |

Si |

Mn |

P/S |

Cr |

| 45# |

0.42-0.50 |

0.17-0.37 |

0.5-0.8 |

<0.035 |

<0.25 |

| 60MN |

0.55-0.65 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

<0.25 |

| B2 |

0.72-0.85 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

0.4-0.6 |

| B3 |

0.58-0.66 |

1.6-1.9 |

0.65-0.8 |

<0.025 |

0.7-0.9 |

Cast Iron balls

| Material |

Chemical Elements |

| C |

Si |

Mn |

P |

S |

Cr |

| Speical Cr 2 |

2.0-3.0 |

< 1.0 |

0.5-2.0 |

<0.08 |

< 0.06 |

> 20 |

| Speical Cr 1 |

2.0-3.0 |

< 1.0 |

0.5-2.0 |

<0.08 |

< 0.06 |

> 15 |

| High Cr |

2.0-3.2 |

< 1.0 |

0.5-2.5 |

<0.08 |

< 0.06 |

> 10 |

| Medium Cr |

2.0-3.2 |

< 1.0 |

0.5-2.5 |

<0.08 |

< 0.06 |

> 5 |

| Low Cr |

2.2-3.4 |

< 1.2 |

0.5-1.5 |

<0.08 |

< 0.06 |

1.0-1.5 |

Grinding Balls For Ball Mill Application( Please let me know your application, Jinan zhongwei will recommend the most high cost-effective type)

- Ball Mill Forged steel ball and cast iron ball

- Mining common use forged steel ball

- Cement Plant common use cast iron ball

- Power Plant forged steel ball and cast iron ball

Competitive advantage:

1.Top high cost performance;

2.Save annual steel ball use qty;

3. Increase outlet derived from the best quality .

Performance comparation:

- Steel Balls for Ball mill can save usage 40-50% than low chrome casting ball(chrome percent: 5%), improve outlet 10% at least than low chrome casting ball.

- Steel Balls for Ball mill can save usage 20-25% than medium chrome casting ball(chrome percent: 5% ~ 10%), improve outlet 10% than medium chrome casting ball.

- Steel Balls for Ball mill can save usage 10% than high chrome casting ball(chrome percent: 5% ~ 10%), improve outlet 10% than high chrome casting ball.

Jinan zhongwei accept any form of the thrid-party testing

Grinding Balls For Ball MillPackage ( Container bags and steel drums are two common used package all over the world,let me know which one you want.)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!