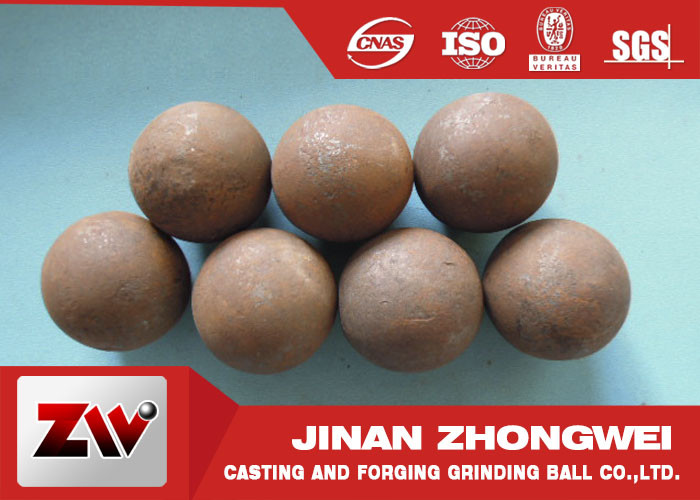

Cement Plant Forged 70mm 120mm 125mm High Hardness Chrome Grinding Media Balls Use in Mine

Product

Forged Ball Details:

Forged steel balls are made by heating the metal to a suitable temperature, applying pressure to the metal blank by forging, causing it to undergo plastic deformation to obtain steel balls with certain mechanical properties, shapes and sizes. This process can eliminate defects such as loose casting produced during the smelting process, optimize the microstructure, and preserve the complete metal flow line, so that the mechanical properties of the forging are better than those of the castings of the same material.

| Material |

Chemical Elements |

|

| C |

Si |

Mn |

P/S |

Cr |

Hardness (HRC) |

| 45# |

0.42-0.50 |

0.17-0.37 |

0.5-0.8 |

<0.035 |

<0.25 |

60-65 |

| 60MN |

0.55-0.65 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

<0.25 |

58-63 |

| B2 |

0.72-0.85 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

0.4-0.6 |

55-58 |

| B3 |

0.58-0.66 |

1.3-1.9 |

0.65-0.8 |

<0.025 |

0.7-0.9

|

56-65 |

| B6 |

0.97-1.03 |

0.2-0.3 |

1.0-1.1 |

<0.025 |

0.5-0.6 |

61-65 |

|

Material

|

25mm-50mm

HRC

|

60mm-90mm

HRC

|

100mm-125mm

HRC

|

130-150mm

HRC

|

| Surface |

Core |

Surface |

Core |

Surface |

Core |

Surface |

Core |

| C45 |

55-58 |

55-58 |

50-68 |

23-30 |

48-52 |

22-26 |

48-52 |

22-25 |

| 60Mn |

58-62 |

55-60 |

58-62 |

30-36 |

57-61 |

26-32 |

57-61 |

26-30 |

| B2 |

60-64 |

58-64 |

57-64 |

45-60 |

55-60 |

38-48 |

55-60 |

38-42 |

| B3 |

62-65 |

60-65 |

60-65 |

58-65 |

56-65 |

50-62 |

56-63 |

50-55 |

| B6 |

62-65 |

60-65 |

61-65 |

58-65 |

60-63 |

50-62 |

61-63 |

50-55 |

Casting Ball

Casting steel balls are made by melting scrap steel, scrap iron and other waste furnace materials using a medium frequency electric furnace, and adding appropriate amounts of precious metal alloys (such as ferrochrome, ferromanganese, ferrovanadium, etc.) during the melting process for chemical composition quenching and tempering. When the molten iron temperature reaches above 1550℃ and meets the process requirements, the qualified molten iron is poured into the steel ball mold, and the spherical iron alloy wear-resistant body is made through quenching, tempering, testing and packaging processes.

1) Traditional Forged

Raw material →Cutting →Heating → Water quenching → Tempering

2) Auto Hot Rolling

Raw material →Hot Rolling Mill → Water Quenching → Tempering

3) Casting

Raw material preparation →Smelting→ Pouring→Cooling and demoulding→Heat treatment and inspection

Test

Packing & Shipping

Steel drum (800-950kg per drum)

Container Bag (1000kg per bag)

Two drums with Pallet

Jinan Zhongwei established in 2000 , we are a leading manufacturer and professional exporter grinding balls in China.

Our company covers an area of 15000 square meters, now we have 150 staff, including 13 technical staff. Annual output is 50000 tons to 80000 tons .

Main products : forged steel ball, cast iron ball ,grinding rod, cylpebs

We have exported to 20 more countries, UAE, Zambia,South Africa, Peru, Chile, Australia, UK, USA, Turkey and so on.

Question and Answer

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q2. Do you have any MOQ limit for the order?

A: 1ton MOQ.

Q3. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!