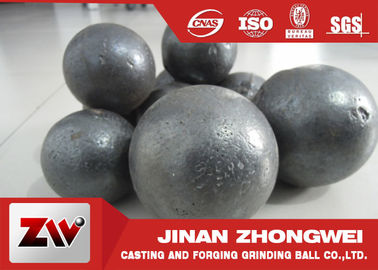

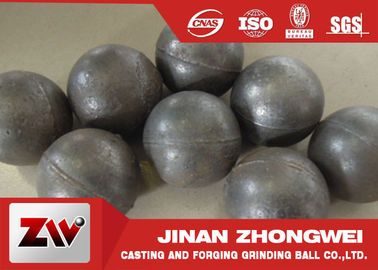

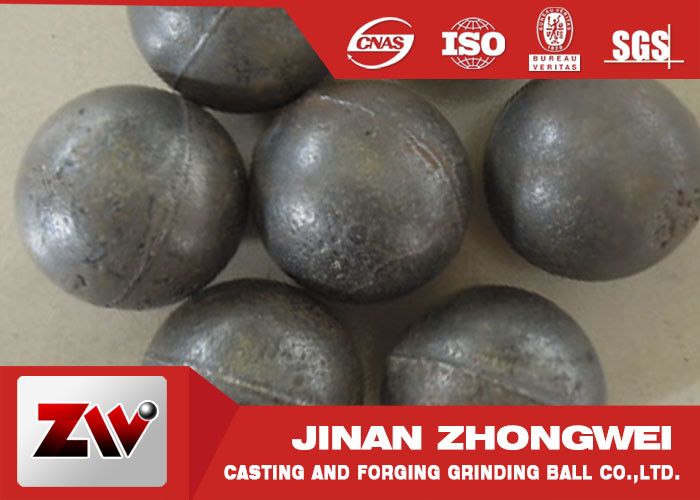

Grinding Balls For Ball Mill with Breakage Rate 1% and Standard GB/T 17445-2009 in High Demand

Product Description:

Grinding steel ball is a main tool for grinding materials, usually used in ball mills. The grinding steel ball produces a grinding effect through the collision and friction between the grinding steel ball and the material, thereby achieving the grinding effect of the material.

Types and uses

Forged steel balls: Made by forging, spinning, rolling, etc., with high strength and wear resistance, widely used in industry and mining fields

Cast steel balls: Produced by casting process, including high chromium steel balls, medium chromium steel balls, low chromium steel balls, etc., suitable for cement, thermal power generation, metallurgy and mining industries

Forged Ball

| Material |

Chemical Elements |

|

| C |

Si |

Mn |

P/S |

Cr |

Hardness (HRC) |

| 45# |

0.42-0.50 |

0.17-0.37 |

0.5-0.8 |

<0.035 |

<0.25 |

60-65 |

| 60MN |

0.55-0.65 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

<0.25 |

58-63 |

| B2 |

0.72-0.85 |

0.17-0.37 |

0.7-1.0 |

<0.04 |

0.4-0.6 |

55-58 |

| B3 |

0.58-0.66 |

1.3-1.9 |

0.65-0.8 |

<0.025 |

0.7-0.9

|

56-65 |

| B6 |

0.97-1.03 |

0.2-0.3 |

1.0-1.1 |

<0.025 |

0.5-0.6 |

61-65 |

|

Material

|

25mm-50mm

HRC

|

60mm-90mm

HRC

|

100mm-125mm

HRC

|

130-150mm

HRC

|

| Surface |

Core |

Surface |

Core |

Surface |

Core |

Surface |

Core |

| C45 |

55-58 |

55-58 |

50-68 |

23-30 |

48-52 |

22-26 |

48-52 |

22-25 |

| 60Mn |

58-62 |

55-60 |

58-62 |

30-36 |

57-61 |

26-32 |

57-61 |

26-30 |

| B2 |

60-64 |

58-64 |

57-64 |

45-60 |

55-60 |

38-48 |

55-60 |

38-42 |

| B3 |

62-65 |

60-65 |

60-65 |

58-65 |

56-65 |

50-62 |

56-63 |

50-55 |

| B6 |

62-65 |

60-65 |

61-65 |

58-65 |

60-63 |

50-62 |

61-63 |

50-55 |

Casting Ball

Technical Parameters:

| Application |

Mining, Ore Mineral Processing |

| Size |

Dia 20-150mm |

| Breakage Rate |

<1% |

| Hardness |

45-65HRC |

| Diameter Tolerance |

±1mm |

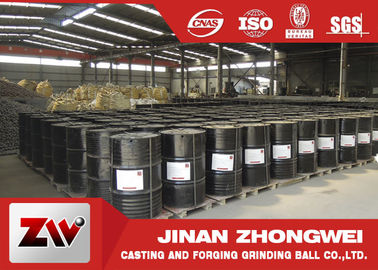

| Packing |

1000kgs in a bag or 850-900kgs in a steel drum, then 25 tons in a 20GP Container |

| Product Category |

Grinding Steel Balls |

| Type |

45#,60Mn B2,B3,B4,B6,low chorm,mideum chorme and so on |

| Standard |

YB/T091-2005, GB/T 17445-2009 |

| Product Name |

Best Quality Excellent Mechanical Performance Mining High Chrome Grinding Steel Ball |

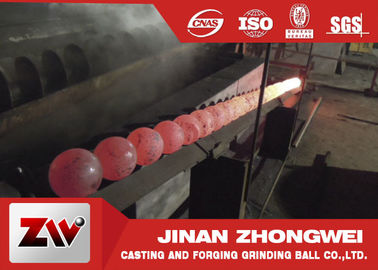

Production Line:

1) Traditional Forged

Raw material →Cutting →Heating → Water quenching → Tempering

2) Auto Hot Rolling

Raw material →Hot Rolling Mill → Water Quenching → Tempering

3) Casting

Raw material preparation →Smelting→ Pouring→Cooling and demoulding→Heat treatment and inspection

Company Information:

Jinan Zhongwei established in 2000 , we are a leading manufacturer and professional exporter grinding balls in China.

Our company covers an area of 15000 square meters, now we have 150 staff, including 13 technical staff. Annual output is 50000 tons to 80000 tons .

Main products : forged steel ball, cast iron ball ,grinding rod, cylpebs

We have exported to 20 more countries, UAE, Zambia,South Africa, Peru, Chile, Australia, UK, USA, Turkey and so on.

Packing and Shipping:

The grinding steel balls are carefully packaged in cardboard boxes to ensure safe transportation and handling. Each box contains a specified quantity of steel balls, securely packed to prevent damage during transit.

Shipping Information:

Once your order is confirmed, the grinding steel balls will be packed and shipped within 1-2 business days. We use reliable courier services to deliver your order promptly and safely to your specified address.

FAQ:

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q2. Do you have any MOQ limit for the order?

A: 1ton MOQ.

Q3. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!